Inventory Systems

Introduction

An inventory management is an organized approach designed to maintain just the right amount of pharmaceutical products in the pharmacy at all times. A key goal of inventory management is to maximize inventory turns while at the same time minimize inventory carrying costs (or holding costs).

Products should be used and not remain on the shelf aging. Although drugs left on the shelf could be considered as financial assets, their useful shelf life wanes with each passing day and excessive inventory is an unproductive asset, tying up money and resources that can be used in running other elements of the pharmacy operation or business as a whole.

A variety of inventory systems are used in pharmacy practice, ranging from simple to complex.

Order Book

When pharmacists or pharmacy technicians identify a product that need to be reordered, they simply write the item in the order book. The listed drugs are then ordered periodically from wholesalers or other suppliers.

- It is highly dependent on the active staff participation.

- It is usually not the sole method of inventory management.

Minimum/Maximum (Par) Level

Relies on a predetermined order quantity and an order point. It is based on the principle that individual drug use falls within a predictable range.- Shelf labels are placed on the storage bin or shelf to alert all staff to the minimum stock quantity.

- When the inventory is reduced to or below the reorder point, designated pharmacy personnel initiate a purchase order to a drug wholesaler.

A computerized database may be employed to manage a par-level system as opposed to shelf stickers and manual accounting.

- Variables such as product availability, contract changes, and changing use patterns (either up or down), make relying on the fully computerized model challenging. Consequently, even the most sophisticated electronic or automated systems require careful human oversight and management.

- Frequent reassessment of the par levels must be conducted to respond to the dynamic nature of patient medication needs.

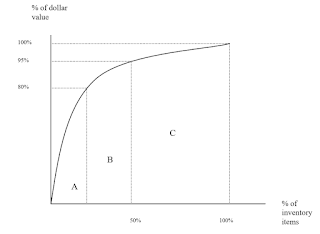

Pareto (ABC) Analysis

The Pareto analysis is based on the 80/20 principles or law of the vital few. This theory states that approximately 80% of most problems can be attributed to roughly 20% of their potential causes.

- Applied to inventory control, the Pareto principle highlights the fact that a relatively small number of drugs account for a disproportionate amount of drug usage (and often times, cost) in a health system. Thus, a Pareto ABC analysis essentially groups inventory products by aggregate value and volume of use into 3 groupings (A, B, and C). This analysis is useful in determining where inventory control efforts are best directed.

- For example, group A may include 10% of all items that make up 70% of the inventory cost. Tight control over these items would be sensible. Group B may include 20% of items and 15% of the inventory cost. An automatic order cycle might be useful here based on well-established par levels. Group C may include 70% of items and 10% of the inventory cost. Less aggressive monitoring of these items may be justifiable.

Economic Order Quantity (EOQ)

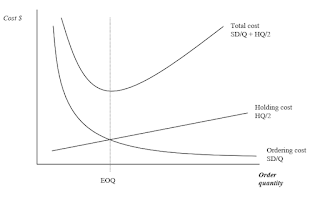

EOQ is another method that attempts to minimize inventory holding costs and ordering costs.

- The EOQ approach (also known as the minimum cost quantity approach) decides inventory order quantities through the use of an accounting formula that calculates the point where the combination of order costs and inventory holding costs is minimized.

- As shown in figure above, the holding cost generally increases and the ordering cost decreases with order quantity. The point where the total cost is minimal represents the economic order quantity (EOQ).

- Assumptions

- The demand for the item is constant over time

- Stockout is not acceptable

- The delivery lead time is known and constant

Just-In-Time Systems

Just-in-time inventory management is a philosophy that simply means products are ordered and delivered when they are needed for patient care with a goal of minimizing wasted steps, labour and cost.

- In case of stock disruptions, a JIT model can have a major impact on the business.

Summary

In real practice, we are probably using multiple inventory systems at pharmacy.

Comments

Post a Comment